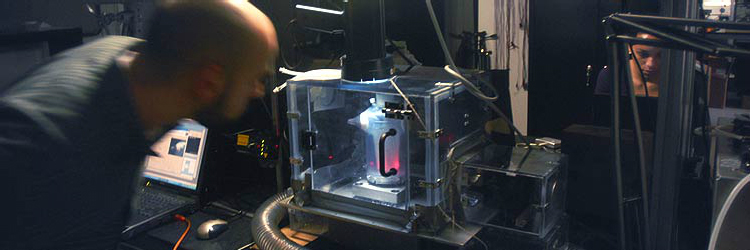

Human Stem Cell Separation Technology

Facilitating promising stem cell therapies

The promise of stem cell therapies hinges on our ability to cost-effectively harvest these cells for beneficial uses. If a patient’s stem cells could be collected in a cost-effective manner, they could be used for a host of regenerative applications, including rebuilding damaged heart muscle and cartilage and healing wounds.